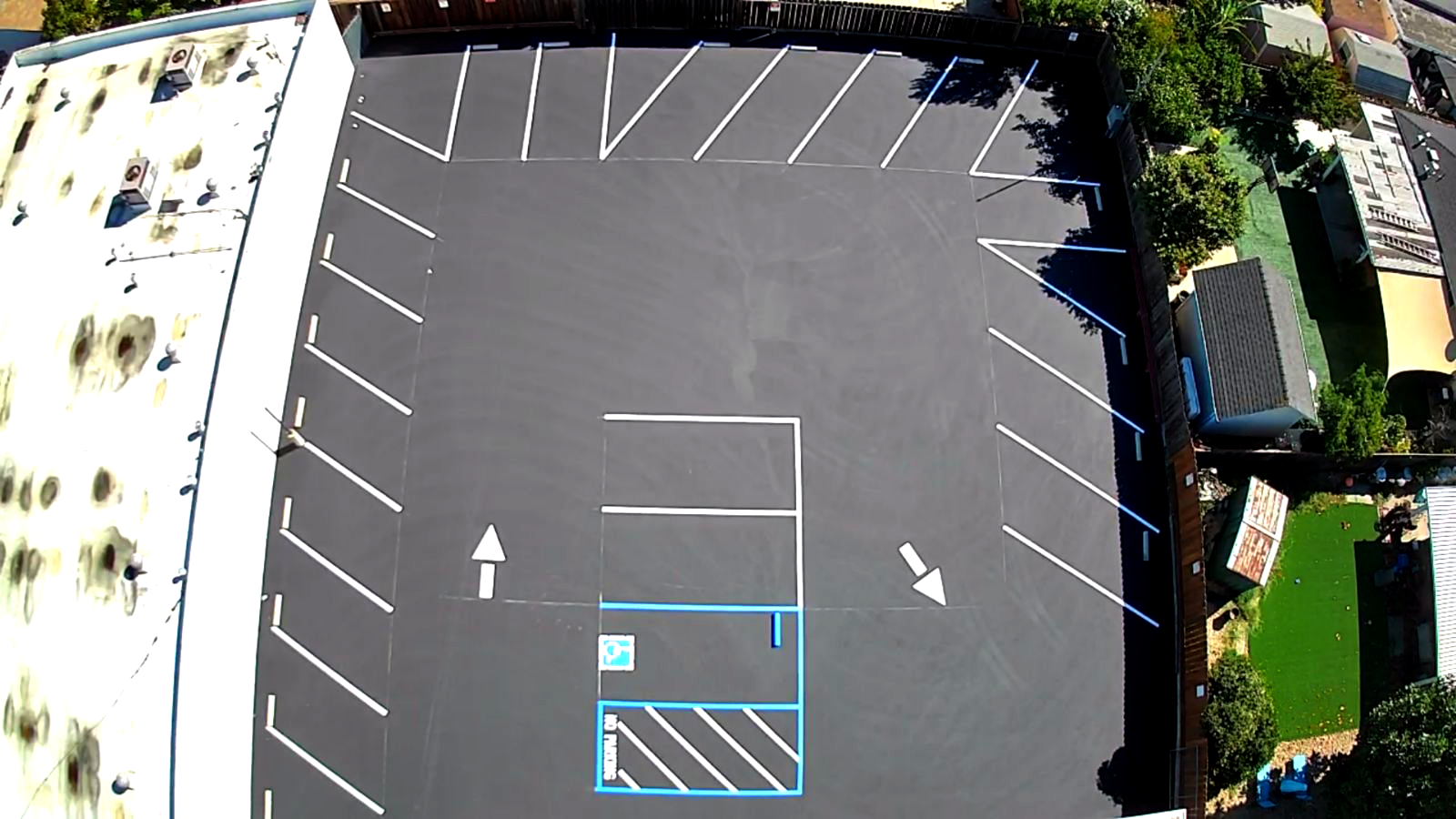

See our work on social media:

Concrete Patio Ideas: Transforming Outdoor Spaces

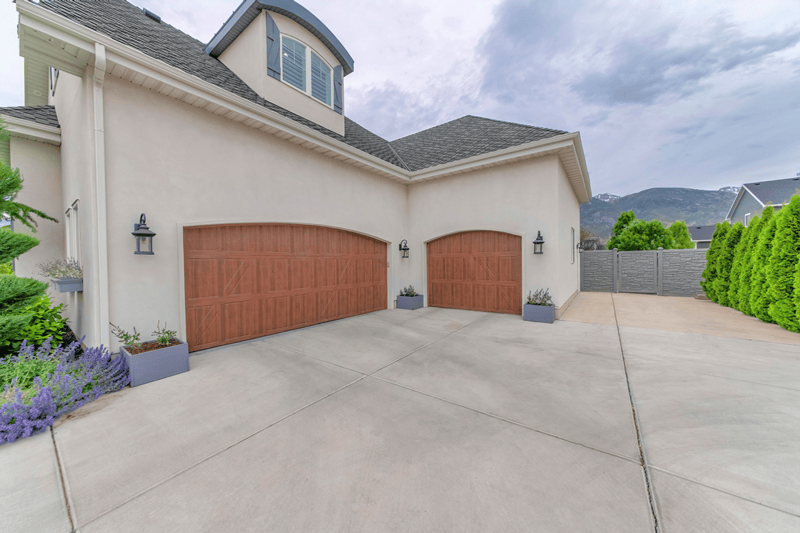

When it comes to creating a stylish and durable outdoor living area, concrete patios are a top choice for homeowners. This blog explores a variety of concrete patio ideas that blend functionality with aesthetic appeal, helping you transform your outdoor space into a beautiful and practical retreat.

Designing with Concrete

Concrete is not just functional; it’s also incredibly versatile. From traditional slabs to decorative stamped designs, concrete patios can be tailored to suit any style and preference. Here’s how you can use concrete to elevate your outdoor spaces:

- Stamped Concrete Patios: Mimic the look of natural stone, brick, or even wood with stamped concrete, which offers a cost-effective way to add a sophisticated touch to your patio.

- Colored Concrete: Enhance your patio’s appeal with colored concrete. Integrating colors into the mix can create a unique, inviting outdoor space that complements your home’s exterior.

- Polished Concrete: For a modern, sleek look, consider polished concrete. Its reflective surface can brighten up any area and make it look more spacious.

Incorporating Functional Features

A patio should be more than just beautiful; it should be functional too. Here are some ideas to enhance the usability of your concrete patio:

- Built-in Seating: Incorporate permanent benches or seating walls to provide plenty of comfortable seating for guests.

- Fire Pits and Fireplaces: Add a central feature like a fire pit or an outdoor fireplace. These features not only provide warmth on chilly evenings but also create a cozy gathering spot.

- Outdoor Kitchens: Turn your patio into the ultimate entertainment zone with an outdoor kitchen. Concrete is highly durable and can easily support heavy appliances and fixtures.

Landscaping and Accessories

Softening the hard look of concrete with the right landscaping and accessories can make a world of difference:

- Planters and Greenery: Use concrete planters or integrate green spaces into your patio design. This not only adds a splash of color but also brings life to your outdoor area.

- Lighting: Proper lighting is crucial for any patio. Integrated LED lights or strategically placed lamps can enhance the ambiance and extend the usability of your patio into the evening.

- Water Features: Incorporate a small fountain or a water wall to add a tranquil element to your patio, making it a perfect place for relaxation.

Maintenance and Care

Concrete patios are low maintenance but require some care to keep them looking their best. Regular cleaning and periodic sealing will protect your patio from weather elements and stains, ensuring it remains beautiful for years to come.

Conclusion

Concrete patios offer endless possibilities for outdoor living spaces. Whether you prefer a minimalist look or a luxurious design with all the amenities, concrete provides a solid foundation that can be customized in numerous ways. Explore these concrete patio ideas to create a space that’s not only functional but also a true extension of your home.

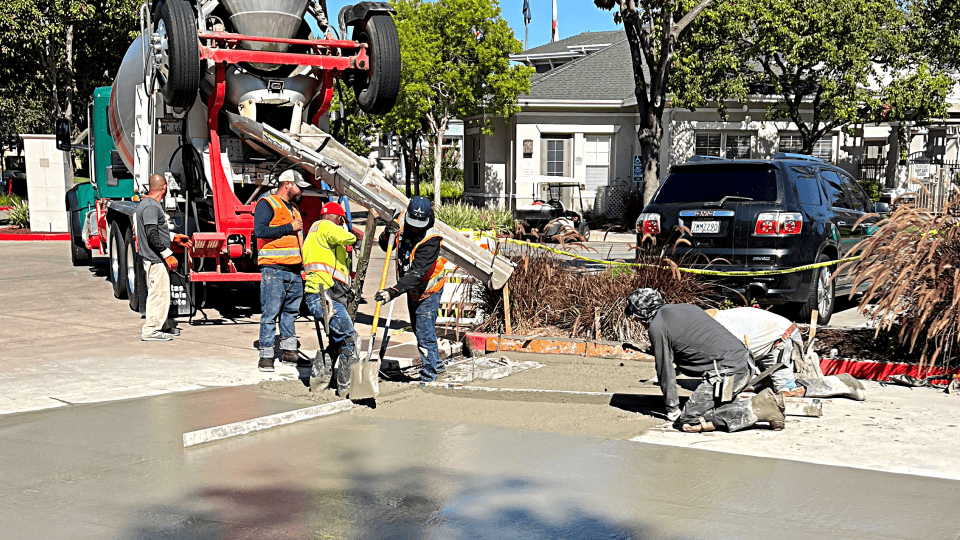

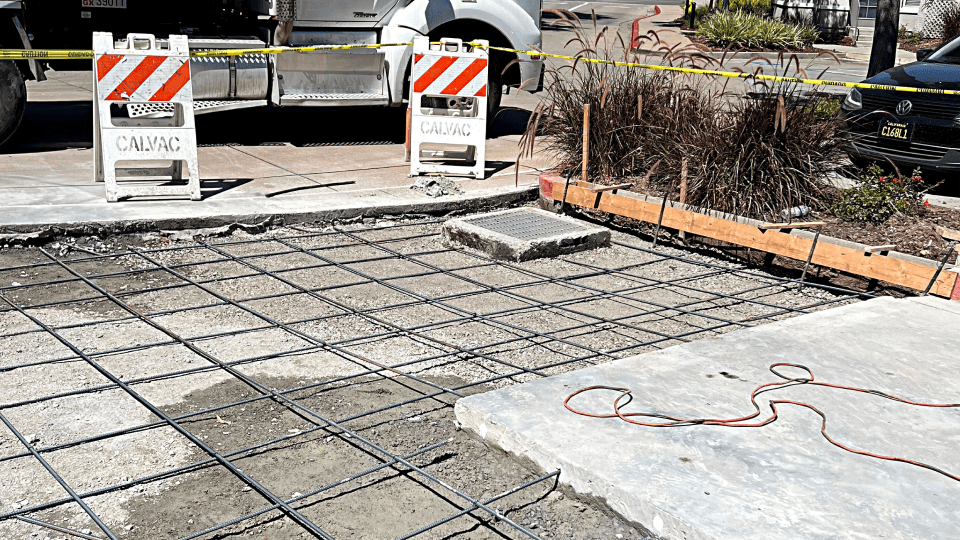

Start Your Concrete Patio With a Free Quote

For more concrete patio ideas and inspiration to elevate your outdoor space, whether you’re aiming for a minimalist design or a fully equipped outdoor entertainment area, we can turn your dreams into reality. Contact Calvac Paving today to start designing your ideal concrete patio.